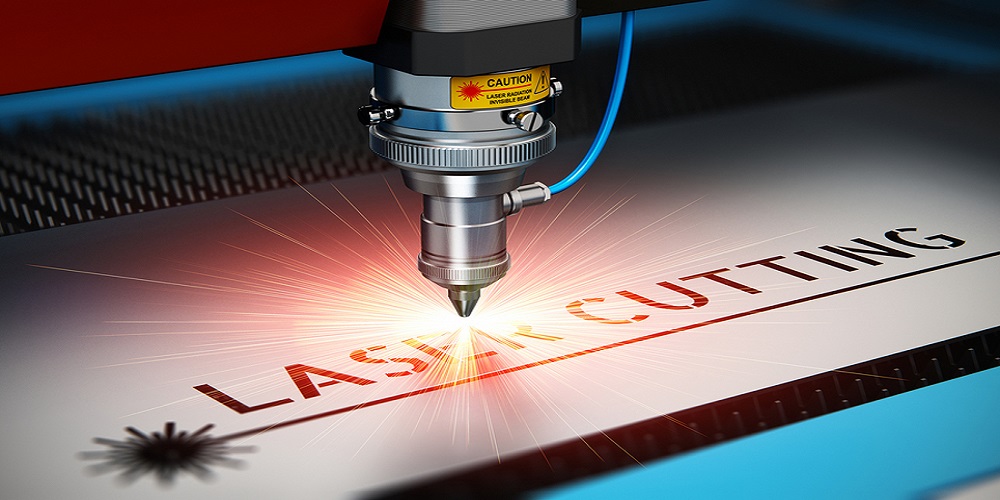

Laser Cutting

The CNC laser cutting machine is used to cut metals such as Mild Steel, Stainless Steel and Aluminum with high precision and speed. Laser provides excellent cut quality and productivity on material less than 16 mm. Laser technology has high capital equipment, running and maintenance costs, therefore a high level of business volume is required to pay back the cost of the equipment.

We have state of the art CNC laser machine makes such as "Trumpf ", Germany. Which can laser cut Sheet metal of varying thicknesses and sizes with bed size is 3 mtrs x 1.5 mtrs.

Our expert team of programmers and operators at each manufacturing location are geared up for execution of complex component laser cutting.

With input as a drawings or a finished sample part provided by customer. We have an independent Online UPS back up of 10 minutes duration for each laser cutting machine which ensures continuity in operation even when there is a power failure. The UPS keeps the machine in operation till changeover is done to DG.