Our Company

We (The Laser Hub) have a dedicated manpower, catering to the needs of our customers. The company employs a dedicated workforce including skilled and semi skilled man power. It stresses on teamwork, which covers all the people involved in the company's day to day working. Backed by a dedicated and diligent workforce and a state-of-the-art infrastructure, we are a trendsetter and trend changer in our specific domain. Having a fully fledged manufacturing unit spread over 10,000 Sq.ft in Hyderabad, state capital of Telangana, India.

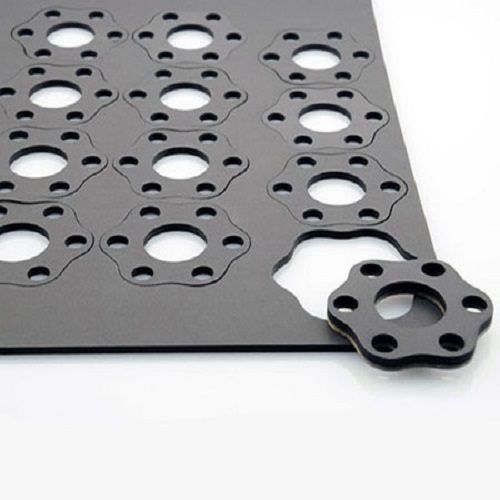

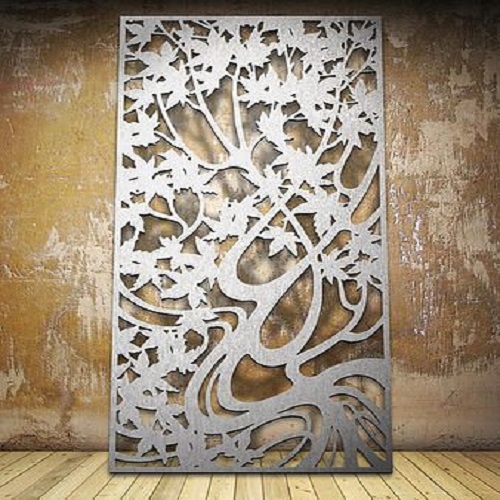

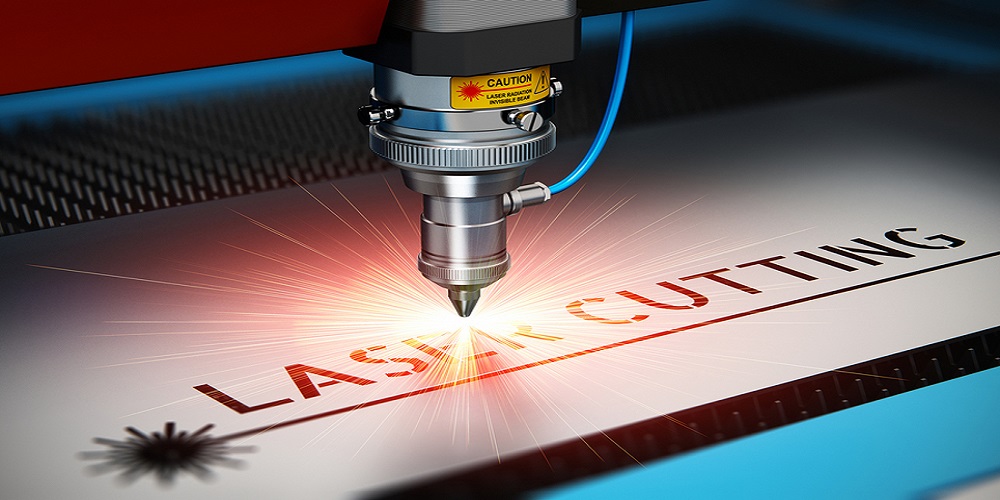

The unit is entirely equipped with all necessary production machinery Like Latest Trumpf Laser Cutting Machine, Hindustan Hydraulic Press-Brake, and numerous supportive machinery with various instruments for quality control. Our one more In house facility is Painting. The manufacturing unit is centrally located which good infrastructure facilities. A well furnished and fully computerized administrative office is located in the plant to co-ordinate all business activities including accounts and finance too. Other departments like design & development, Q.C, Stores are placed within the manufacturing unit.

We aim to focus on developing products that exceed our customer’s expectation of tomorrow, while meeting their current requirements. We believe in fully understanding our customer’s needs and providing our valuable services to meet them. Our passion is for customer delight.

Contact Us

THE LASER HUB

99854 55770

98859 88850

Email: baba.laser@gmail.com

Plot No: C-12/B, IDA Uppal

Hyderabad 500039